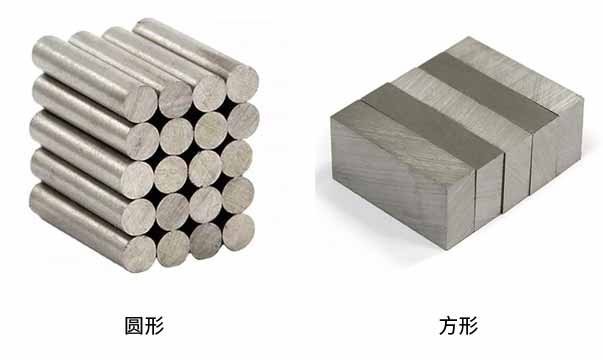

Aluminum nickel cobalt permanent magnet is an alloy composed of aluminum, nickel, cobalt, iron, and other trace metal elements. The composition of its metal components is different, and its magnetic properties are also different, resulting in different uses. There are three different production processes for aluminum nickel cobalt permanent magnets: casting, sintering, and bonding. The casting process can be processed and produced into different sizes and shapes. Compared to the casting process, sintered products are limited to small sizes, resulting in small dimensional tolerances for the produced rough products and good casting processability. In permanent magnet materials, cast aluminum nickel cobalt permanent magnets have the lowest reversible temperature coefficient and can operate at temperatures above 500 degrees Celsius. Aluminum nickel cobalt permanent magnet products are widely used in various instruments and other high-temperature resistant applications.

Guangdong QS-Mag Technology Co., Ltd Copyright@ Copyright Reserveds Technical Support:E-WIN